How to make soap

Written the 8th of November 2025

Introduction

Today Chiara and I decided to make soap. Well, it has been quite some time actually since we wanted to make it. I’m writing this guide based on my experience in the hope of helping anyone who wants to make soap 😊.

First off, there are some things to keep in mind when making soap. As we are dealing with chemicals here, you really should work in a safe environment with safety protections and follow the instructions by word (without skipping anything).

Another thing is, to have the chemical reactions to actually happen, you’ll need to follow the quantities as they are, this is not a food receipt 😉.

Ingredients and tools

List of necessary stuff:

- box (silicone, or wood weared with baking paper)

- baking paper

- latex/nitrile gloves

- protection glasses

- mask

- plastic container

- knife

- precision balance

- sodium hydroxide

- silicone spatula

- immersion blender

- olive oil

- water

- essential oil (optional)

- colored mica powder (optional)

Sodium hydroxide, olive oil, water and essential oils must be measured according to this table (italian).

The quantities exposed below are what

Chiara

and I used in the making process of the soap, but you must calculate them yourself.

Math

1 l of olive oil = 916 g

The saponification value (SV) of olive oil is 0.134

Sodium hydroxide = olive oil x SV = 122.744 g

Because the soap we are making will be used to wash hands, we have to apply a discount of 4.5% to the sodium hydroxide:

Discounted sodium hydroxide = sodium hydroxide - sodium hydroxide x 4.5% = 117.22052 g

Water = 30% x olive oil = 274.8 g

1 g of essential oil = 1.25 ml

Essential oil = water x 3% = 8.244 g

8.244 g of essential oil = 10.305 ml

Process

First off wear the protection glasses, mask and gloves to protect yourself.

Also wear the box with the baking paper, this is where the soap will be poured before saponification.

Start by pouring the measured water into the plastic container, now slowly pour sodium hydroxide into the container (never do the opposite, pouring water into sodium hydroxide is dangerous), and start mixing with the silicone spatula until the sodium hydroxide completely dissolves. Note the reaction is happening and the temperature increasing (reaching 90 degrees). Make sure not to breathe the released chemicals in the air, keep windows open during this process.

Pour the measured olive oil into the container, then mix with the spatula.

Now take the immersion blender and start mixing everything, mix until the composition looks like “cream”. Now it’s time to add the essential oil into the composition, if you want you can also add the colored mica powder to color out the soap, then mix again with the blender.

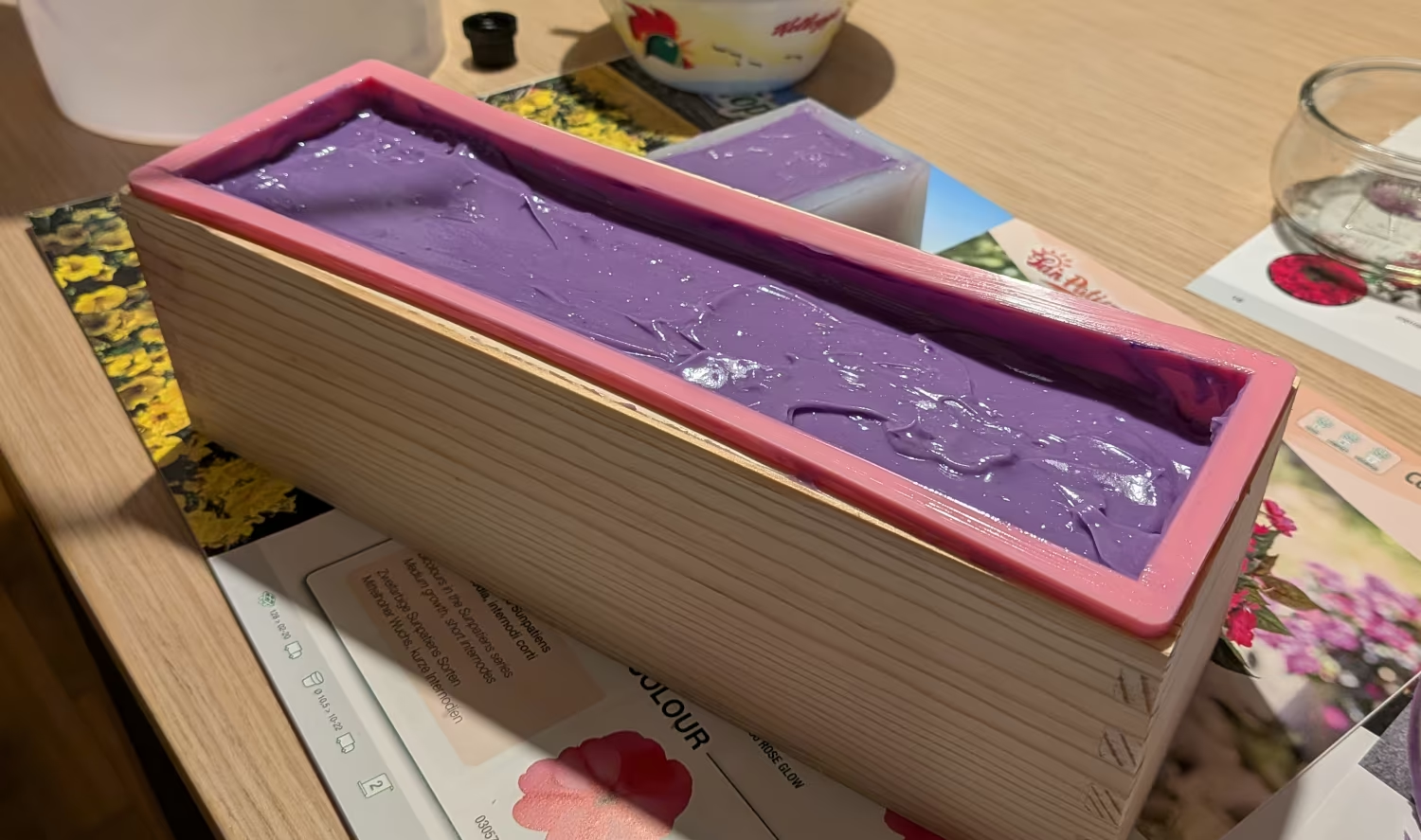

Pour the composition into the box we prepared earlier and close it. This is when the saponification process takes place, you’ll need to leave it untouched for 24 hours.

After such time, take the soap out of the box, still using gloves, and cut it using the knife.

The box we used is 28 cm long, which means 11 soaps are created if you cut every 2.5cm (recommended), although we have cut it every 2 cm in the example.

Now leave them separated and resting for 30 days, this is a necessary step because it makes soap lose water and become harder, which will make it last longer.

Conclusions

What you get is a nice and cheap piece of soap 😊, to wash your hands whenever you need.

Have fun!